Thermal Wall Cooling System

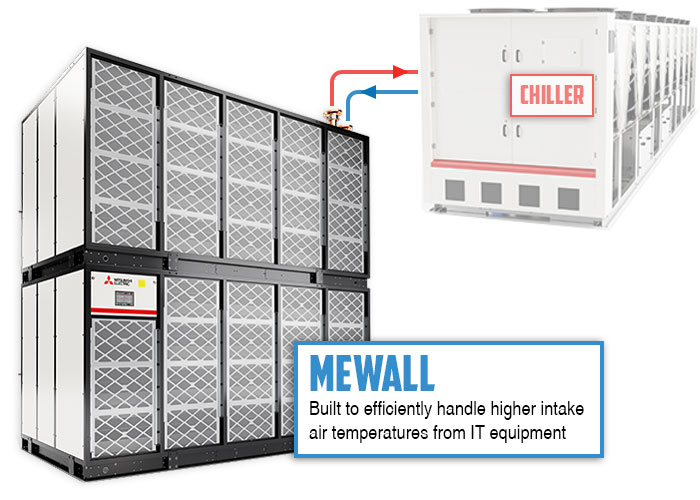

The MEWALL redefines high-density cooling capacity to meet the increasing demands on hyperscale and colocation data centers.

Thermal Wall Cooling System

The MEWALL redefines high-density cooling capacity to meet the increasing demands on hyperscale and colocation data centers.

Precision Cooling for High-Density IT Loads

In our fast-paced digital world, soaring power demands require data centers to deploy highly efficient, reliable, and scalable cooling systems – or they risk high energy costs, overheating and catstrophic downtime.

Mitsubishi Electric’s thermal wall solution, MEWALL, is engineered to meet these challenges with unmatched efficiency and reliability.

Available in two models (402 & 462), the MEWALL systems are highly efficent chilled water cooling solutions designed to meet the unprecedented cooling demands of large scale, high performance data centers.

Each thermal wall unit consists of two stacked modules optimized to handle higher intake air temperatures and control leaving air temperatures to improve your data center’s energy efficiency.

Optimize space, enhance energy efficiency, and simplify installation and maintenance – all while ensuring continuous, reliable operation with Mitsubishi Electric’s MEWALL.

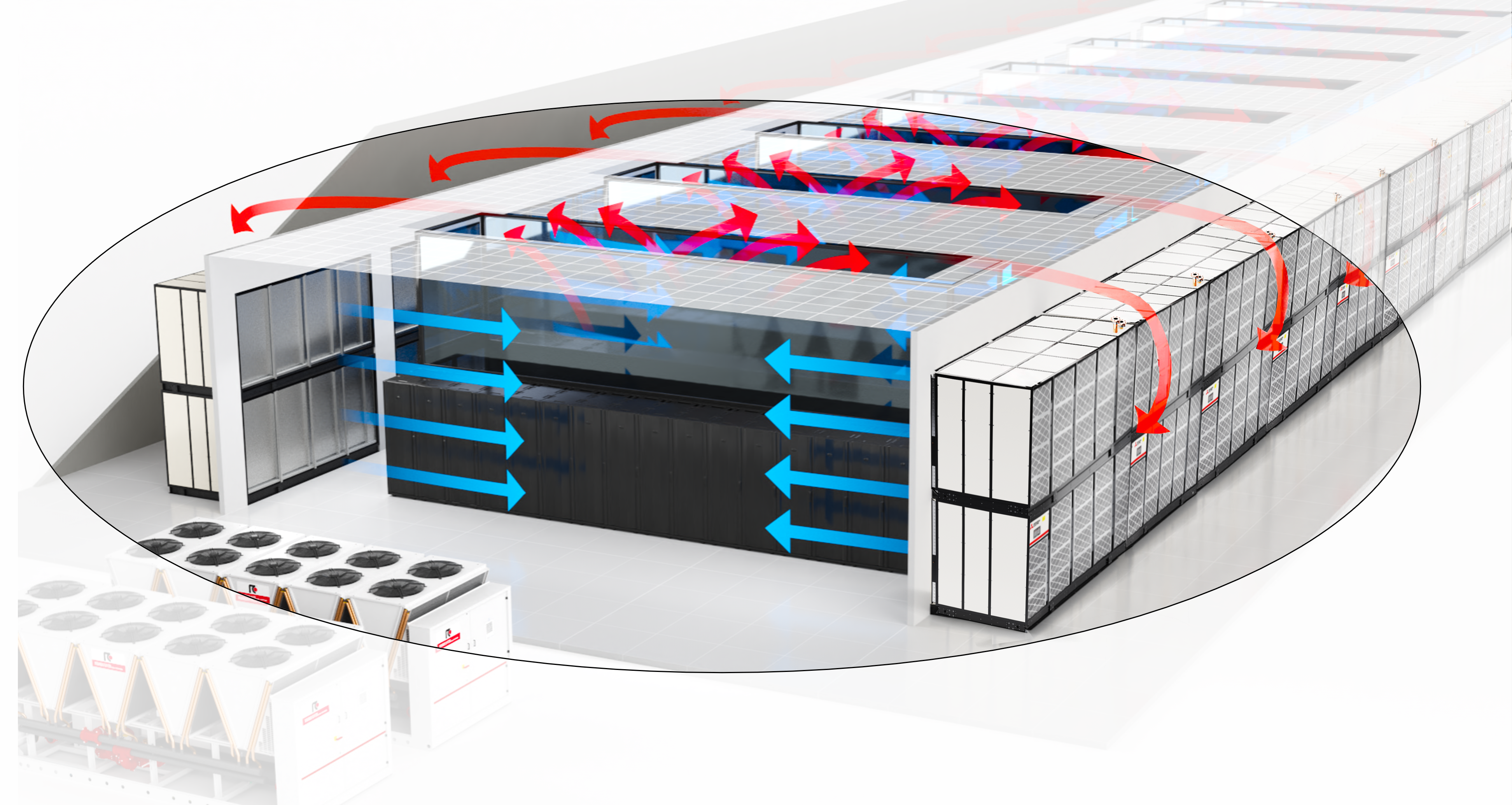

As a critical element of a chilled water cooling system, the MEWALL is designed to work seamlessly with chillers to handle higher intake temperatures and improve the efficiency of water-cooled data centers.

Unlock High Efficiency Cooling Capacity with a Thermal Wall System

Thermal wall cooling systems are essential for effective and efficient airflow management and temperature control in your data center.

The MEWALL is designed to optimize your data center layout, delivering uniform cooling across your entire IT environment and preventing overheating – even with taller server racks.

To enhance airflow performance, the MEWALL offers the following control strategies, which are optional and can be deployed as needed:

- Maintain Constant Airflow Rate: Control airflow by measuring and comparing the static pressure before the fan intake and at the inlet ring, adjusting the fan speed to maintain desired airflow.

- Maintain Differential Pressure: Manage airflow by measuring static pressure between high-pressure areas (e.g., the cold aisle and the front of the server) and low-pressure areas (e.g., the hot aisle and the rear of the server cabinets). Fan speed will increase or decrease if differential pressure drops below or exceeds your target.

This strategic cooling method is key to maintaining operational efficiency and reducing energy costs, while ensuring the reliable performance and longevity of your IT equipment and critical power systems.

Redefine High-Density Cooling Capacity

MEWALL’s compact, strategic design is purpose-built to achieve new levels of high-density data center cooling while reducing installation complexity and increasing white space for additional server racks.

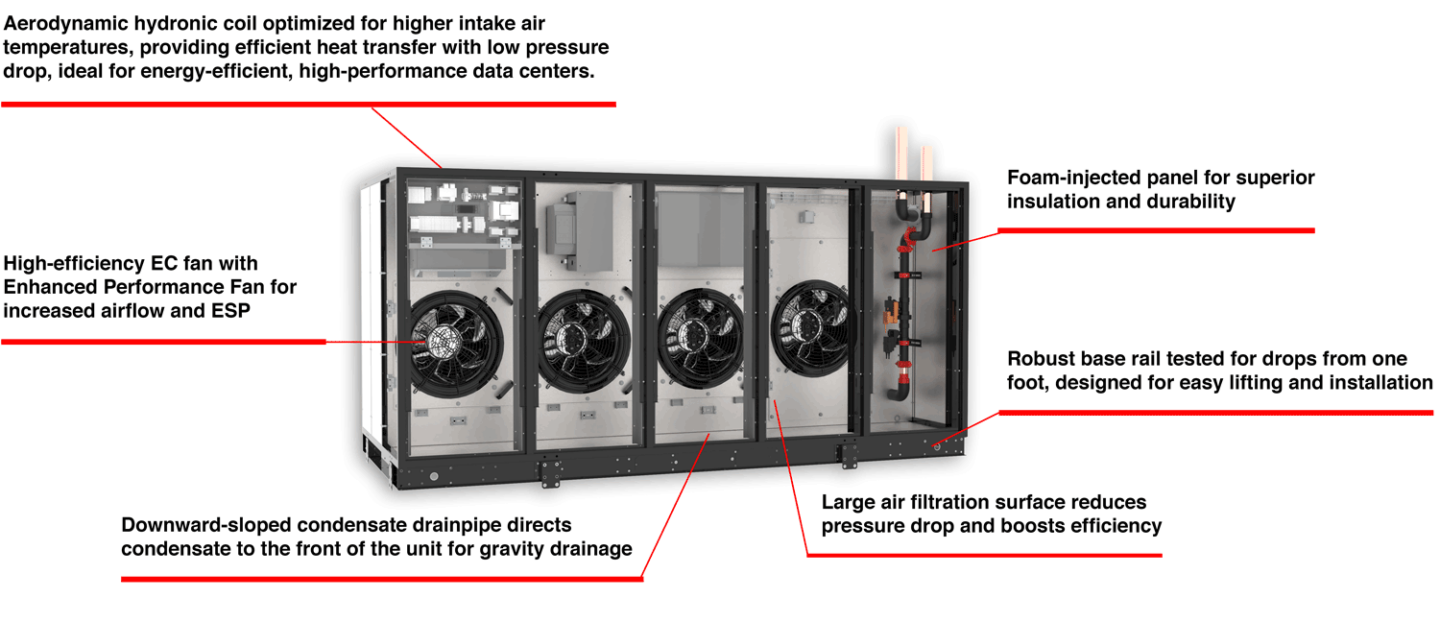

Our thermal wall units possess a high air filtering surface and are designed to be stacked. Further increase your cooling capacity per foot and reduce maintenance costs with zero side clearance between units.

The MEWALL doesn’t require a raised floor and is installed in a mechanical gallery rather than in the white space. Combined with its low leaving air velocity, this setup reduces turbulence and significantly shortens the distance between the unit and the first row of IT cabinets—maximizing usable floor space for IT equipment.

The MEWALL: Resilient Data Center Cooling

Maximize Uptime with Enhanced Reliability

Ensure reliable operation with built-in redundancy and fail-safe features.

- The MEWALL’s multi-fan setup and two independent cooling modules ensure uninterrupted cooling.

- A dual power supply with a factory-installed automatic transfer switch maintains power if an outage occurs.

- Restart time is minimized with UltraCap® or external power-ready options to keep control systems running.

Minimize Downtime with Easy Access & Maintenance

Lower your TCO and minimize downtime with convenient front access to critical components, such as electrical components, filters, fans, and coils.

- Our accessible thermal wall design features innovative hinged (tilted) EC fans and a front access inspection door system to frequently serviced components without removing side panels.

Improve PUE with Optimized Performance

- Compact and highly efficient EC fans feature variable-speed operation, optimizing energy use by adjusting to airflow needs.

- An electronic pressure-independent valve (EPIV) delivers real-time cooling performance monitoring and maintains a constant water flow regardless of variations in pressure.

- The MEWALL is designed to work with high performance chillers operating at higher water temperatures, increasing overall energy efficiency

Flexible Deployment & Easy Installation with Adaptable Design

- Our two thermal wall models cover the same footprint, seamlessly integrating into data center design to scale as needed.

- Ensure quick and seamless setup with pre-installed piping and control valves with quick-connect flange and Victaulic® connections

High Customization for Optimized Data Center Cooling

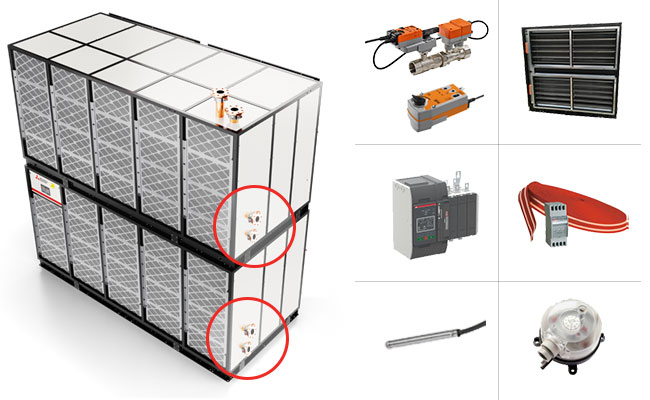

This thermal wall system is your data center cooling solution: it’s purpose-built via full customization of the water coils, hydronic connections, valves, dampers, and more.

Optional side hydronic connections on either the right or left side of the fan wall accommodate any water piping layout. Four hydronic connections are required (2 inlet and 2 outlet).

For detailed specifications and available options, access the full MEWALL Specification document.

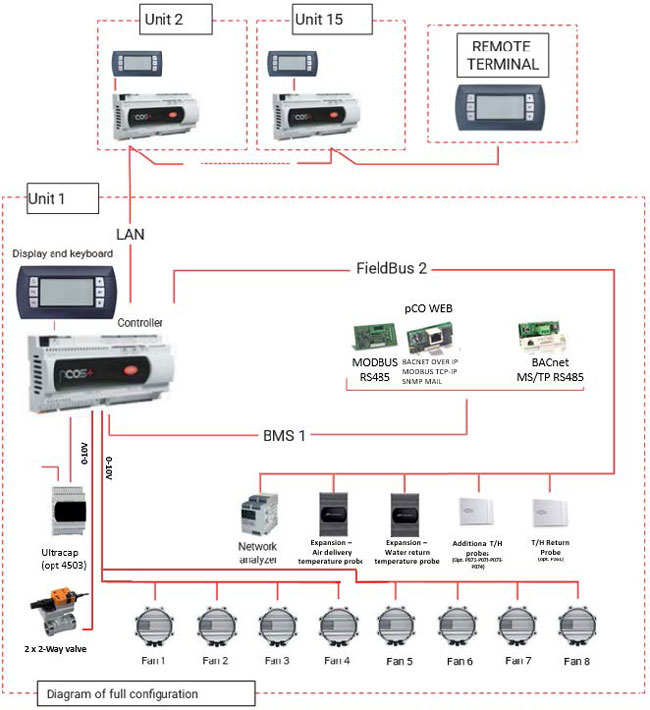

State-of-the-Art Control System

The MEWALL is equipped with a controller connected to a 6-key keyboard or upgrade to a 7-in touch screen graphic display and KIPlink interface with remote monitoring through your web browser.

- The controller’s flash memory can register up to 200 events and preserves the information even in the absence of power supply.

- Through the optional serial port, the microprocessor control enables communication with modern building BMS systems with the following protocols: MODBUS; BACNET MS/TP RS485; and BACNET OVER IP.

Thermal Wall Group Control Functions

The control system offers LAN connectivity for up to 15 thermal wall units! From a shared remote terminal, you can optimize load distribution, manage alarms, and control backup/standby units.

The MEWALL easily performs a variety of group control functions that translate into increased efficiency, reliability, and cost savings.

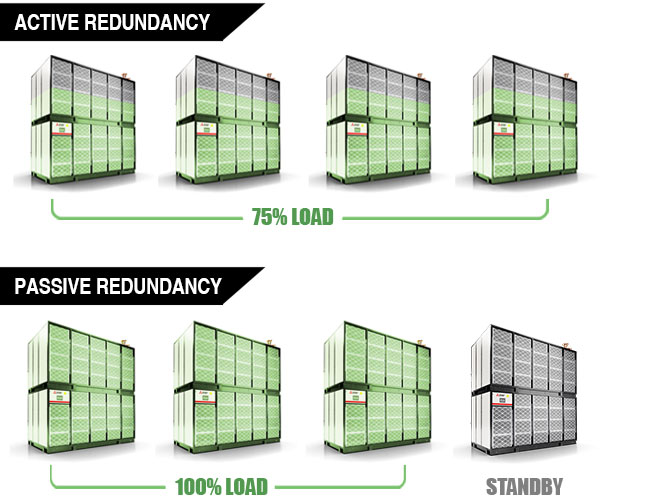

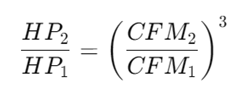

Optimizes energy efficiency by balancing the cooling load across all units in the control group, including standby units. By running all units at lower speeds, the system takes advantage of the cube law relationship between energy consumption and fan speed, reducing energy loss compared to turning off unused units. In case of a unit failure, the system automatically increases the speed of the remaining units to maintain the desired temperature, ensuring cooling capacity is maintained.

Here’s how Active Load Distribution can translate into energy cost savings:

Fan Affinity Law 3 states that power (horsepower) varies with the cube of the airflow change:

Here’s is an example assuming each AHU is equipped with 40 HP motors:

PASSIVE REDUNDANCY – Operating only active units (standby units are off)

- Total HP = 40 HP x 3 units = 120 HP

- For 120 HP motor at 90% efficiency, Power Consumption = 99.47 kW x 8,760 hours = 871,350 kWh

- At an average rate of $0.135 per kWh, the Total Cost = $117,630

ACTIVE REDUNDANCY – Load distributed across all units (including standby unit)

- Total HP = 0.4219 x 40 HP x 4 units = 67.5 HP

- For 67.5 HP motor at 90% efficiency, Power Consumption = 55.96 kW x 8,760 hours = 490,210 kWh

- At an average rate of $0.135 per kWh, the Total Cost = $66,180 ($51,450 savings!)

Allows units to independently adjust their operation to correct localized hot or cold spots when their temperature deviates beyond a preconfigured threshold from the average temperature. This adjustment is made without disrupting the overall system. Once the temperature normalizes, the unit seamlessly reintegrates into group control.

Adjusts fan speeds based on air pressure readings to maintain consistent static pressure across all units. It ensures stable airflow by synchronizing the fan speeds of units in the group to meet the required pressure levels, which can be set to maximum, minimum, or average values. This optimizes cooling efficiency and ensures uniform airflow throughout the system.

Adjusts fan speeds based on return air temperature readings to maintain the correct temperature levels across all units. It calculates the average, maximum, or minimum return temperatures from the group and adjusts fan speeds accordingly. This ensures uniform cooling and effective temperature regulation throughout the system.

Elevate Your Data Center Cooling Strategy

The MEWALL is a high-quality thermal wall system ready to be fully customized to best suit your data center’s cooling needs, all while lowering your TCO.

Wondering what a MEWALL purpose-built for you looks like?

Our Project Application team will work directly with you to understand your cooling targets and the various characteristics of your environment.

- What is your Cooling Capacity target?

- What are the Working Condition Temperatures? (Entry Air Temp & Leaving Air Temp + Entry Water Temp & Leaving Water Temp)

- What fluid type is used? (e.g. pure water or water with glycol)

Let’s talk data center cooling!

MEWALL Technical Documentation

The MEWALL is designed for high-density, high efficiency, and high customization. Review the various documentation below for detailed technical information about this indoor cooling unit.

| Model | 402 | 462 | ||

|---|---|---|---|---|

| Base Performance Fan | Enhanced Performance Fan | Base Performance Fan | Enhanced Performance Fan | |

| H (in) | 138 | 157 | ||

| L (in) | 142 | 142 | ||

| D (in) | 63 | 63 | ||

| Airside Delta T = 20°F | ||||

| CFM Range | 41,000-58,681 | 41,000-61,801 | 45,000-64,744 | 45,000-70,629 |

| Net Sensible Cooling Capacity (KW) | 251-355 | 251-377 | 285-376 | 285-412 |

| Airside Delta T = 25°F | ||||

| CFM Range | 41,000-58,681 | 41,000-61,801 | 45,000-64,744 | 45,000-70,629 |

| Net Sensible Cooling Capacity (KW) | 313-476 | 313-518 | 344-506 | 344-552 |

Disclaimer: The performance of the Mitsubishi Electric MEWALL is influenced by factors such as air and fluid side design temperatures, glycol percentage, site altitude, and external static pressure requirements. Please consider these variables when evaluating performance data and contact the Mitsubishi Electric Cooling Team for project-specific performance information.

Specification

For even more information, please fill out this form and the document will be emailed to you.

By submitting this contact form, you agree that a representative(s) of Mitsubishi Electric Power Products, Inc. (MEPPI) may contact you using the information you provided. In accordance with our Privacy Policy, we will never share or sell your personal data.