The Runaway Review

Join Product Manager, JJ Hocken, as he reviews batteries and discusses the advantages and disadvantages of various chemistries impacting the UPS industry.

The Runaway Review

Join Product Manager, JJ Hocken, as he reviews batteries and discusses the advantages and disadvantages of various chemistries impacting the UPS industry.

Sodium-Ion

Sodium-ion development dates back to the 1970s and early 1980s. However, in the 1990s, Lithium-ion batteries showed more commercial promise, causing a decline in interest for Sodium-ion. In the 2010s, Sodium-ion batteries experienced a newfound interest, largely driven by the increasing cost of Lithium-ion.

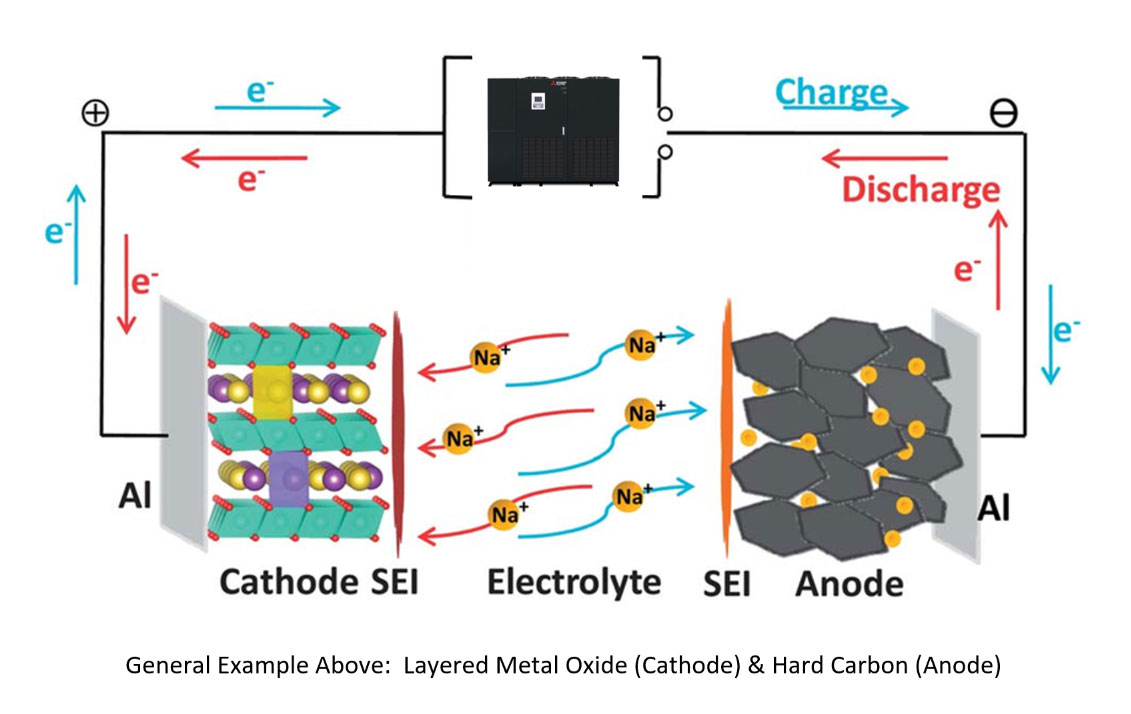

Like Lithium-ion batteries, Sodium-ion batteries also consist of two active electrodes: The anode and the cathode in which the chemical storage of energy takes place.

The anode and cathode are separated to prevent short circuits between the active materials. The separator material can be a variety of insulating materials with good sodium-ion conductivity.

Like lithium-ion and its assortment of chemistries designs, Sodium-ion does not refer to one single chemistry. There are various types of Sodium-ion batteries being developed and researched and, in this edition of The Runaway Review, will go over just a few of the major types.

Even though Sodium-ion batteries are very similar to Lithium-ion batteries in overall design and structure, there are some differences that are important to understand:

- Sodium-ion batteries, unlike Lithium-ion batteries, cannot use graphite for anodes as the ions cannot be deposited cleanly in the graphite interlayers.

- Aluminum can be used in Sodium-ion for the anode current collector unlike Lithium-ion which can only use copper.

- Sodium-ion batteries can use safer aqueous electrolyte, but this results in limited energy densities.

- The anode for Sodium-ion batteries can range from metal oxides, Prussian blue analogues, or porous hard carbon.

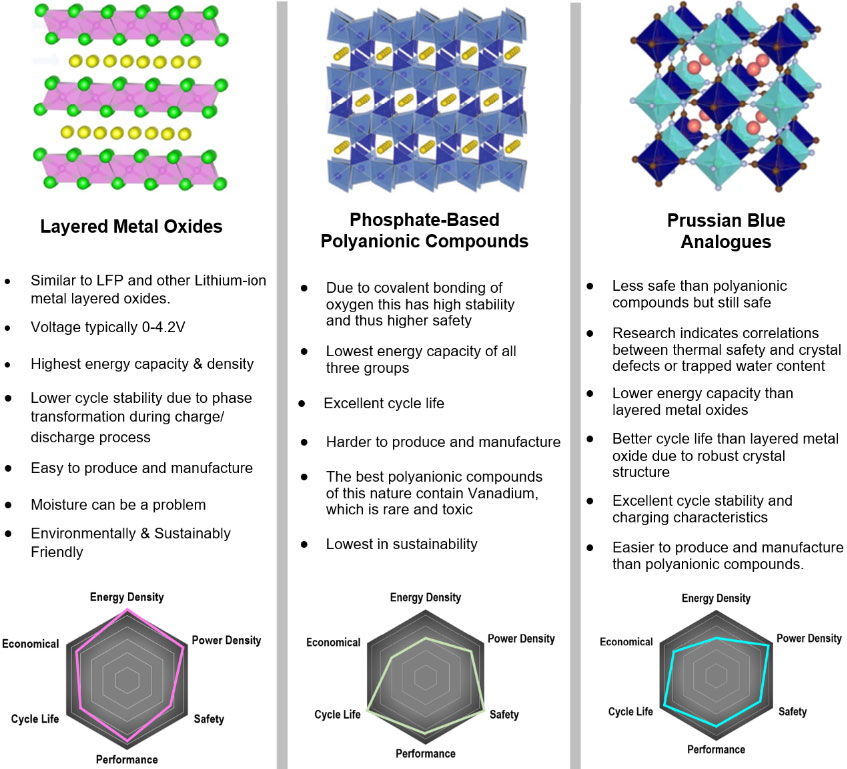

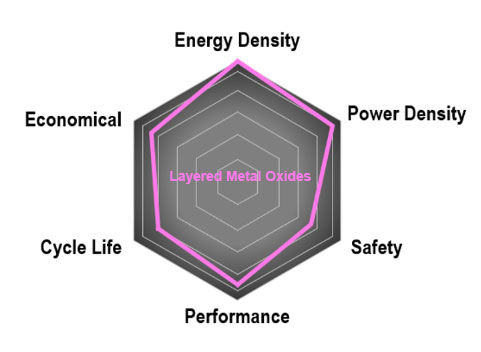

Currently, the three most popular Sodium-ion batteries sorted by their cathode materials are:

Sources:

Layered Metal Oxides: Zuo, W., Qiu, J., Liu, X. et al. The stability of P2-layered sodium transition metal oxides in ambient atmospheres. Nat Commun 11, 3544 (2020). https://doi.org/10.1038/s41467-020-17290-6

Phosphate-Based Polyanionic Compounds: Ni, Qiao & Bai, Ying & Wu, Feng & Wu, Chuan. (2017). Polyanion-Type Electrode Materials for Sodium-Ion Batteries. Advanced Science. 4. 1600275. 10.1002/advs.201600275. https://www.researchgate.net/figure/Crystal-structure-of-phosphate-based-compounds-with-Fe-a-triphylite-type-NaLi-FePO-4_fig12_312925098

Prussian Bule Analogues: Wang, W., Gang, Y., Hu, Z. et al. Reversible structural evolution of sodium-rich rhombohedral Prussian blue for sodium-ion batteries. Nat Commun 11, 980 (2020). https://doi.org/10.1038/s41467-020-14444-4

In UPS applications, there are three main Sodium-ion battery chemistries currently being pursued:

1. Layered Metal Oxide (Cathode) w. Hard Cardon (Anode)

The first type has a layered metal oxide cathode, and the anode is typically made from hard or porous carbon. This battery:

- Has thermal safety properties and attributes very similar to Lithium-ion batteries

- Will have great energy capacity and power density

- Is used in some EVs or other energy dependent technologies

Compared to VRLA, this chemistry has superior cycle life, design life, energy capacity, and power density.

If used for UPS applications, it would be made for a 10-15-minute runtime battery, depending on design and overall system application. For now, layered metal oxide with a hard carbon anode battery design are not generally applied in UPS applications on a large scale, but this may change over time.

Attributes of this chemistry in the UPS industry

|

|

|

|

|

Moderate risk of fire propagation and thermal runaway This is due to the carbon anode and the phase transformation during charge/discharge process.

|

|

|

Lower in cost than Lithium-ion (brand and manufacturer dependent) |

|

|

Cycle life could be in the thousands of cycles (6,000+ cycles; use case dependent)

|

|

|

Generally, this chemistry has a higher operating temperature range than Lithium-ion (brand and manufacturer dependent).

|

|

Medium – high power density |

|

|

High energy capacity This is an attribute that research is trying to increase as it is still lower than some Lithium-ion chemistries. |

|

|

Could be used for 10-15-minute+ runtime battery systems |

2. Prussian Blue/White (Cathode) w. Hard Carbon (Anode)

The second type has a Prussian blue or white cathode, and the anode is typically made from hard or porous carbon. This battery:

- Has thermal safety properties and attributes very similar to Lithium-ion batteries due to the hard carbon used as an anode.

- Has a lower energy capacity than the Prussian white

- Has a power density that is on par with Lithium Iron Phosphate (LFP) batteries overall

Compared to VRLA, this chemistry has superior cycle life, design life, energy capacity, and power density.

This type of Sodium-ion battery was to be released in the EV industry, but it has not been used in the UPS industry. If used for UPS applications, it would be made for a 5-10-minute runtime battery depending on design and overall system application.

Attributes of this chemistry in the UPS industry

|

|

|

|

|

Moderate risk of fire propagation and thermal runaway This is due to the carbon anode.

|

|

|

Lower in cost than Lithium-ion (brand and manufacturer dependent) |

|

|

Cycle life could be in the thousands of cycles (8,000+ cycles; use case dependent)

|

|

|

Generally, this chemistry has a higher operating temperature range than Lithium-ion (brand and manufacturer dependent).

|

|

Medium – high power density |

|

|

High energy capacity This is an attribute that research is trying to increase as it is still lower than some Lithium-ion chemistries. |

|

|

Could be used for 10-15-minute+ runtime battery systems |

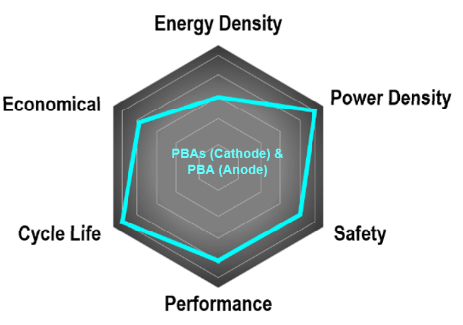

3. Prussian Blue (Cathode) w. Prussian Blue (Anode)

The third type is now gaining popularity in the UPS industry, and it uses a special blend of sodium, called Prussian Blue Analogues (PBAs), to make the cathode and anode.

This special material helps the battery exchange electrons easier and greatly enhances the discharge and charging properties of the battery. However, this reduces the energy capacity of the battery.

The special cathode and anode reduce the chemical friction in the transfer of power and, in turn, decreases the thermal safety risk. There could be some thermal risk though as research indicates correlations between thermal safety and crystal defects or trapped water content in the crystalline structure of Prussian blue.

The battery design also uses an aqueous electrolyte. The battery is designed for sub-5-minute runtimes and for power density UPS applications that do not require a lot of energy capacity. This type of battery is currently being applied to UPS system applications.

Compared to VRLA, this chemistry has superior cycle life, design life, energy capacity, and power density.

Attributes of this chemistry in the UPS Industry

|

|

|

|

|

Little to no risk of fire propagation and thermal runaway

|

|

|

Higher cost This is due to the special cathode and anode materials |

|

|

Cycle life could be in the thousands of cycles (10,000+ cycles; use case dependent)

|

|

|

Higher operating temperature range than Lithium-ion (0°C – 45°C) |

|

High power density |

|

|

Lower energy capacity than Type 1 and Type 2 Sodium-ion (discussed above) and Lithium-ion batteries |

|

|

Typically, used for sub-5-minute runtime battery systems |

Sustainability

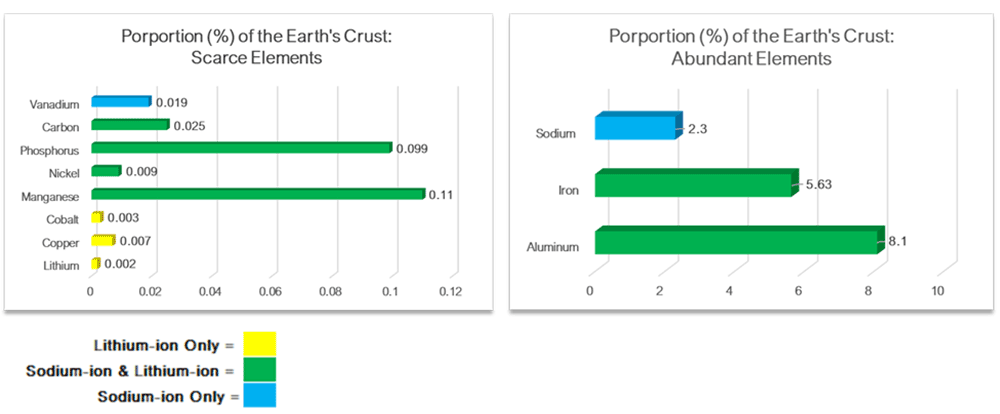

The charts below show how abundant the raw materials for Lithium-ion and Sodium-ion batteries are in the earth’s crust.

In general, the elements used in Lithium-ion batteries are scarce compared to the elements in Sodium-ion batteries. Vanadium, which is rare and toxic and often used in phosphate-based polyanionic cathodes in Sodium-ion batteries, is the exception.

*Note: Lithium-ion chemistry LFP does not require cobalt and performs better than other Lithium-ion battery chemistries in terms of scarce elements used.

Fewer or no critical raw materials are used in the Sodium-ion battery. Also, Sodium-ion eliminates the following highly criticized Lithium-ion traits:

- High-water consumption during extraction of lithium

- Child labor during mining of cobalt

Sodium-ion batteries are not yet superior in terms of greenhouse gas emissions due to the lower energy density. As Sodium-ion batteries are mass produced, this may result in considerable increases in efficiency, which may translate to improvements in greenhouse gas emissions overall.

The various chemistries of Sodium-ion are, in general, superior in sustainability aspects.

Conclusion

Sodium-ion batteries possess amazing power density attributes and are a safe alternative to both Pure Lead VRLA and Lithium-ion batteries. Specifically, the chemistries with a layered metal oxide cathode and hard carbon anode have exciting properties that rival LFP and other Lithium-ion battery chemistries.

The Prussian Blue cathode and anode type, specifically, is making its way onto the UPS market now and is a good choice for customers that don’t necessarily need a 5-minute battery but want the added safety and charging characteristics.

Mitsubishi Electric’s analysis believes that Sodium-ion batteries, in general, have a better sustainability and environmental impact than Lithium-ion.

It is important to note that, just like Lithium-ion, there are a variety of chemistries that comprise the overall category of “Sodium-ion batteries.” This means that not all Sodium-ion batteries have the same characteristics or cost – and some are still in the pre-mass production stage.

It is also critical to be mindful of your use case and understand the cycle and charge rates of the chemistry you implement. Respect your battery system and in turn it will provide you with safe and reliable backup power.

Wondering which UPS battery chemistry is best for your application? Check out this post on How to Select the Best UPS Battery Backup.

We Want to Hear from You!

We take great pride in offering the most reliable critical power solutions to our customers – and understanding your battery backup needs helps us do that. Help us shape the future of our UPS battery technology offering by filling out this quick 3-question Voice of the Customer form 👇

*By clicking this link, you will be redirected to GetFeedback, a survey software. This is completely anonymous unless you identify yourself at the end of the survey.

References

ACS Omega 2022, 7, 7, 5605–5614, Publication Date: February 11, 2022

https://doi.org/10.1021/acsomega.1c05794

Copyright © 2022 The Authors. Published by American Chemical Society.

This publication is licensed under CC-BY-NC-ND 4.0.

The big beginner’s guide to Sodium-Ion batteries – FutureBatteryLab

Layered Metal Oxides: Zuo, W., Qiu, J., Liu, X. et al. The stability of P2-layered sodium transition metal oxides in ambient atmospheres. Nat Commun 11, 3544 (2020). https://doi.org/10.1038/s41467-020-17290-6

Phosphate-Based Polyanionic Compounds: Ni, Qiao & Bai, Ying & Wu, Feng & Wu, Chuan. (2017). Polyanion-Type Electrode Materials for Sodium-Ion Batteries. Advanced Science. 4. 1600275. 10.1002/advs.201600275. https://www.researchgate.net/figure/Crystal-structure-of-phosphate-based-compounds-with-Fe-a-triphylite-type-NaLi-FePO-4_fig12_312925098

Prussian Bule Analogues: Wang, W., Gang, Y., Hu, Z. et al. Reversible structural evolution of sodium-rich rhombohedral Prussian blue for sodium-ion batteries. Nat Commun 11, 980 (2020). https://doi.org/10.1038/s41467-020-14444-4

Zeng, Xianguang & Peng, Jing & Guo, Yi & Zhu, Huafeng & Huang, Xi. (2020). Research Progress on Na3V2(PO4)3 Cathode Material of Sodium Ion Battery. Frontiers in Chemistry. 8. 635. 10.3389/fchem.2020.00635.

Edited by Nicole Kristof, Senior Marketing Specialist

Stay up-to-date on industry trends & insights

Be the first notified of new blog posts

By submitting this contact form, you agree that a representative(s) of Mitsubishi Electric Power Products, Inc. (MEPPI) may contact you using the information you provided. In accordance with our Privacy Policy, we will never share or sell your personal data.