BLOG

BLOG

Performing a Total cost of ownership Analysis

Consider what goes into any major purchase, such as a car, home or an Uninterruptible Power Supply (UPS): the starting point for most is selling price.

Beyond selling price, other costs, such as insurance, fuel, electricity, maintenance, and term of ownership are essential to a complete evaluation.

You may not realize it, but when you consider these things, you’re performing a Total Cost of Ownership (TCO) analysis.

TCO includes the purchase price of the asset plus the future cost over a target term. You can see what the total cost of ownership will be over a specific time, such as 15 years.

This method helps identify variable costs over the life of the purchase. This process can also be used as a method for direct comparison of two or more assets as part of an evaluation and decision-making process.

For purchasers of critical backup power systems, like a UPS, the TCO analysis is an effective decision-making tool when considering a design or design change. The process can help validate or exclude design variations for your data center’s UPS.

Drilling down further, we look at two main classifications for the TCO:

Capital Expense (CAPX)

- Purchase Price

- First & Recurring Costs

Operational Expense (OPEX)

- Considers ongoing maintenance and consumables

Let’s see how applying a TCO analysis can assist in the evaluation of two options for a 2.0MW modularized UPS requirement.

Background

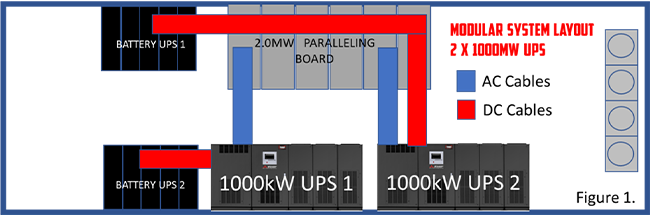

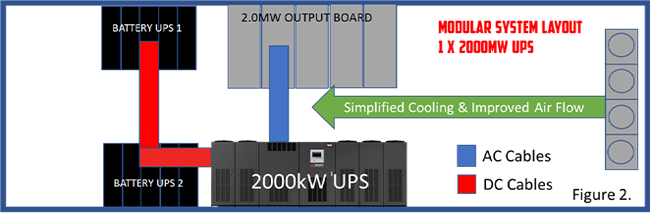

A favorite and common UPS building block rating is 2000kW (2.0MW). UPS critical bus capacity of 2.0MW can be accomplished by either paralleling for capacity two 1000kW UPS (Figure 1) or by using one 2000kW UPS (Figure 2). Both designs support a 2.0MW critical load. For this example, our current design utilizes 2 x 1000kW UPS (Figure 1). Changing to 1 x 2000kW UPS (Figure 2) is under consideration.

2.0MW critical load, installed and integrated into a pre-fabricated enclosure.

Our goal is to determine if changing from a 2 x 1000kW parallel UPS (current design, Figure 1) to a 1 x 2000kW UPS (Figure 2) will yield a lower cost of ownership. First off, when moving to a single UPS, all things required for paralleling go away.

- The paralleling board (switchboard) is eliminated.

- The number of system breakers is reduced.

- The communications between UPS modules is no longer needed.

- Installation becomes simplified as the input and output cable length matching requirement is eliminated.

- Space is gained by no longer needing paralleling compensation magnetics / line reactors or paralleling gear and possessing a smaller UPS footprint.

Enclosure or modular applications have the additional challenge of ensuring all (battery, UPS, bypass, cooling, etc.) fit in the enclosure. The single 2.0MW design requires less space. Not only is the switchgear smaller, but the UPS lineup reduces by as much as 10 feet in length! The cooling load is smaller, and airflow is more effective – all positive attributes for modular deployments.

Last, but not least, OPEX. Testing and commissioning one UPS vs. a parallel system takes less time and helps with on-time project delivery. Warranty, maintenance, and power cost for one module are less.

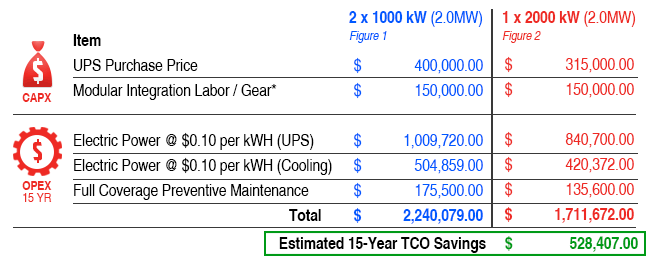

To build the TCO analysis, we consider all the items identified (1 – 9) listed below. Table 1 adds the associated costs (CAPX and OPEX) for a completed Total Cost of Ownership.

- Reduced UPS First Cost

- Improved airflow in the enclosure allows for more effective cooling for long-term operation success

- Elimination of input/output power cable length matching; Reduction in power cable required and elimination of the concern/need/space for line reactors

- Overall reduction in the number of input/output power conductors required; Reduction in material and installation labor costs and ease of installation with one UPS vs two

- Elimination of paralleling board; Breaker count reduction and simpler/faster systems commissioning

- Reduction in UPS footprint, improving overall layout of total system

- Elimination of paralleling communications, and thus, simplifying installation

- Reduction in electrical operational costs

- Reduction in PM and maintenance costs

Table 1

*Shown as an additional cost

Battery replacement not included / net $0 difference.

All prices listed are for comparison purposes.

As you can see, a TCO analysis is an effective tool for validation and/or exclusion when looking to compare different designs or options. The TCO exercise above helps us see an estimated 25% TCO savings over the 15-year term.

So, is your data center power design costing you extra money?

TCO Savings from selecting a 1x2MW Configuration

Summary

- Reductions in power cabling runs

- Elimination of input impedance matching

- Reduced electrical power consumption

- Removal of the paralleling board

- Decrease in startup, installation, commissioning, and maintenance time

Electrical power usage at .10 cents per kWh / 100% load (2.0MW) offers an estimated electrical savings to be as much as $250,000.00 over 15 years.

Edited by Nicole Kristof, Senior Marketing Specialist

Stay up-to-date on industry trends & insights

Be the first notified of new blog posts

By submitting this contact form, you agree that a representative(s) of Mitsubishi Electric Power Products, Inc. (MEPPI) may contact you using the information you provided. In accordance with our Privacy Policy, we will never share or sell your personal data.