BLOG

BLOG

It’s that time of year; temperatures outside are dropping and furnaces are kicking on.

So, you go throughout your house and adjust your dampers.

However, you might not need all that hot air blowing in your upstairs office, so you close the damper.

After all, the upstairs of the house is always the warmest because hot air rises.

So, why is it that in modular electrical shelters we see comfort cooling through wall coolers with upflow cooling?

In this method, the cold air delivery is on the top, and the warm air return is on the bottom. This goes against the natural thermal movement of air.

Some pieces of equipment that require cooling, such as an uninterruptible power supply (UPS) will use fans to draw air from the front grille and exhaust out the top. If your cold air delivery is coming from a top supply and you have warm air exhausted from the top, you’re going to see significant mixing of air.

These scenarios may lead to hot spots throughout the modular room, which can increase operating costs as your cooling system may need to work harder to compensate for these hot spots and mixing.

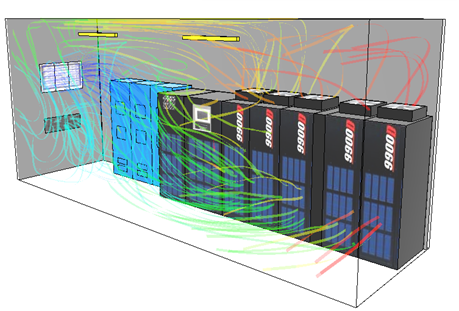

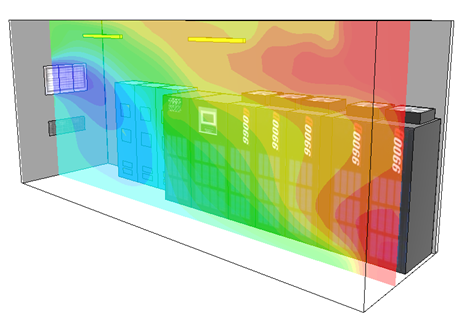

The simulation below shows a top flow delivery that is cooling a UPS. There is a significant mixing of air; the air exhaust of the UPS is mixing with the cold air delivery window.

As a result, this mixing can create a large temperature gradient in front of the equipment, creating hot spots.

Mitsubishi Electric’s DX-P can avoid the air mixing in this particular application.

In the DX-P’s downflow design, cold air is delivered from the bottom grille, and warm air is returned from the top.

This design allows for optimized airflow and cooling performance by delivering cold air where it is needed (in front of your equipment) and capturing the warm air where it naturally rises to, preventing the mixing of air in the building.

Some equipment, such as lithium ion batteries have very specific operating ambient temperature requirements.

Failure to maintain the manufacturer’s temperature requirements could have warranty implications.

Delivering cold air directly to equipment helps mitigate that risk and ensures the equipment stays at the right temperature.

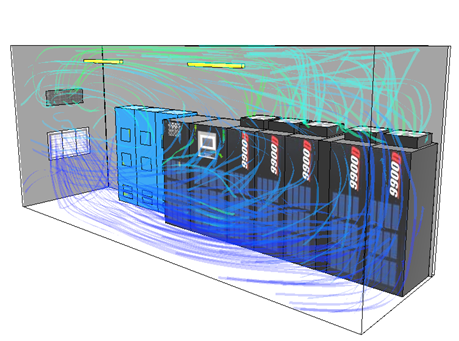

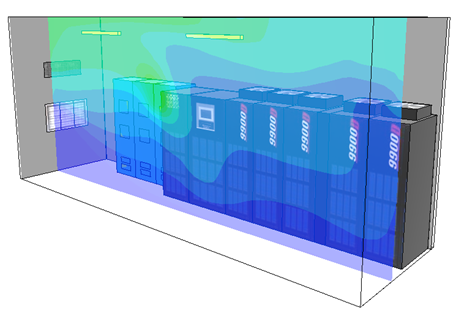

A downflow cold air delivery design is shown in the simulation below. The warm air return is capturing the UPS exhaust heat at the top. As a result, there is minimal mixing of air.

The temperature gradient remains cooler, eliminating high temperature hot spots as shown in the upflow simulation above. This method creates a cooler climate, prolonging your equipment life and maintaining warranty.

Perhaps your modular building has IT servers installed in it. By deploying the downflow design, we can create a cold/hot aisle containment configuration, similar to a data hall in a traditional data center.

So, does this mean that your upflow air cooler is inherently bad? Not necessarily.

Upflow air delivery is a tried-and-true method, particularly in rooms that don’t have equipment using forced air cooling. In some applications, you can duct from the top grille throughout the building and put the cold air where you need it, such as in Battery Energy Storage Systems (BESS).

Fortunately for you, Mitsubishi Electric can offer either solution. We’ll take the guess work away from you, so you can have the peace of mind knowing that your cooling product is the right fit.

Edited by Nicole Kristof, Senior Marketing Specialist

Stay up-to-date on industry trends & insights

Be the first notified of new blog posts

By submitting this contact form, you agree that a representative(s) of Mitsubishi Electric Power Products, Inc. (MEPPI) may contact you using the information you provided. In accordance with our Privacy Policy, we will never share or sell your personal data.