Meet Johnny

Our team members come from diverse and experienced backgrounds in electrical training, and many have been in critical power for years. We pride ourselves on choosing the best people to service our customers to ensure that you get the most out of your equipment.

Meet Johnny

Our team members come from diverse and experienced backgrounds in electrical training, and many have been in critical power for years. We pride ourselves on choosing the best people to service our customers to ensure that you get the most out of your equipment.

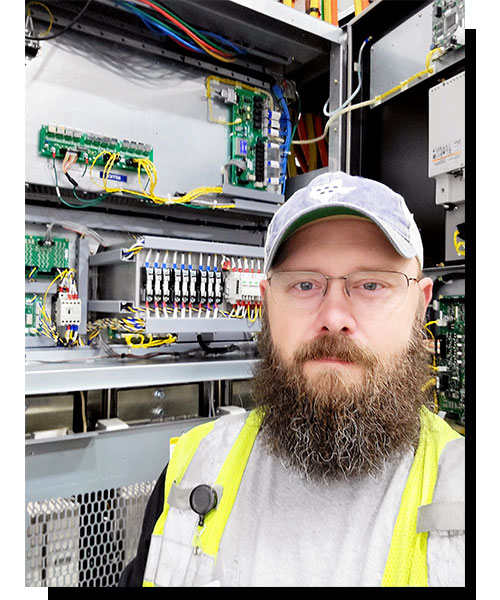

Johnny Mallory

Region: Central

After retiring from the Navy after 20 years as a Chief Fire Controlman, Johnny Mallory began his career in critical power with Mitsubishi Electric about 5 years ago. As a jack of all trades, he has accumulated multiple degrees and certifications which speak to his varied experiences and knowledge that he brings to the Critical Power Solutions Division.

Certifications

AAS in Electromechanical Technology, Bachelor in Professional Studies in Technology Management, Department of Labor Journey License as an Electromechanical Technician, Samsung Batteries, Cellwatch, NFPA-70, OSHA 30

Field Trained

9900D; 9900C/CX; 9900B; 9900AEGIS; 9900A; 1100 Series; SUMMIT Series®

Where are you from?

“I’m originally from Richmond VA but spent 20 years in the Navy and retired to New Braunfels Texas-between San Antonio and Austin.

I retired as a Chief Fire Controlman, which is an electronics technician who controls the firing of weapons.”

How did you find Mitsubishi Electricand start working in the critical power industry?

“I found a job posting on a Facebook page for Navy Veterans that were in the electronics fields.”

What drew you to the role?

“I was going on sites like Glassdoor and looked up Mitsubishi. Mitsubishi had a really good reputation as far as what people were writing on the reviews and they were nice enough to hire me.

The job sounded - from what the post was - exactly like what I was doing in the Navy but without the weapon system - and it turned out to be similar, without blowing stuff up. I knew the recruiter who hired me, and he knew what the job was, so he convinced me to apply for it.”

What sets Mitsubishi Electric apart from other brands in the industry?

“The fact that the UPS work when they are supposed to! I always hear from customers that the Mitsubishi UPS are battle tanks, unlike other brands that might blow up if you look at it wrong.”

In your opinion, what sets our Field Service team apart?

“The support we get from our leadership, the family feeling that the service department has. Most of us are veterans.

I’ve only been working on UPS for like 5 years [and] I have 20 years of experience working in electronics. A lot of times, I’ll find myself in a new situation where I haven’t come across it yet and it’s not in any of the books that Mitsubishi provides us, so I’ll call a bunch of the guys I know around the country and ask them for their help.

Every time I call on somebody, every time somebody calls me, we always seem to drop what we’re doing to answer the phone and help out, and if they don’t know it, they’ll point me in the direction of the person that does know the answer.

A lot of times, I call Erik Goudie or Chang Kim or Tony Sellers or a lot of guys on the west coast I’ll call sometimes if I know it’s late in the afternoon, and it’s still early for them. So, for me, it felt like a big family network and everyone’s willing to help everyone.”

Can you talk more about the training process?

“[It] is dependent on your level of knowledge and like, for me, I already knew a lot about electronics and had some knowledge - the weapon systems I used had UPS but not the same scale as what we do. Chris Rishack has an excellent program which pretty much goes through every square inch of our UPS. And he’s very thorough when teaching us most of what we need to learn for each UPS.

There’s usually 2-3 days of classroom work where Chris teaches - goes through PowerPoints, explaining what each part does, the operation of the UPS and then we go through a day or two of getting our hands on the UPS, different parts of it, seeing which voltages come from where, how to operate it, how to run different tests on it, stuff like that. Mitsubishi has an excellent training pipeline."

Do you think that Service is a big contributor to our reliability overall? The fact that we’re not only reliable in product, but also in Service?

"From what I’ve seen out in the field, we’re really one of the only companies that give high quality training to our service techs, then we follow it up with [a] 40-hour shadowing where we have to follow somebody around who has experience and get them to sign off that we know the equipment well enough to be by ourselves to work on it.

Whereas other companies I’ve seen out in the field, they’ll send guys out to work on UPS who have no experience, have never seen a UPS - or our UPS in particular - and a lot of times, that’s what gets them in trouble, and they end up blowing it up and causing a load to drop or something. Then they call us.”

In what ways has the critical power industry changed since you’ve started? What do you think will change in the next few years?

“Since I started 4-5 years ago, it seems like the UPS have gotten smaller but can handle higher loads. Lithium batteries have also exploded on the scene. I see newer battery technology replacing the current available options.”

Mitsubishi Electric does a lot of work in data/ colocation centers. What other industries do you expect will see an increase in need for critical power? Why?

“I see a lot of hospitals needing back up for their MRI/CT scanners. I can see a need for communication industries like radio stations or phone companies to need our UPS in case of the need to get emergency notices out to the public.”

What is something that people may find surprising or interesting about working in critical power?

“It’s satisfying work that takes you to some cool random places…that work on advanced technology for the space industry or the electrical vehicle industry. I’ve been [to] so many random places like middle of nowhere Nebraska where the oil industry has pump stations hidden in corn fields and all you can see to the horizon miles away is corn.

Or getting to work in multiple sports arenas around Texas has been an eye-opening experience with seeing what’s behind the curtain in the areas that the general public doesn’t get to travel. I also do a lot of work at fire stations, military bases, airports...”

What’s the most interesting place you’ve been to?

“The observatory up in the mountains of West Texas. I’m originally from Virginia and I’ve been stationed all over the country with the Navy, but I’ve always wanted to live in Texas. I always thought Texas was this flat country - sage brush and cactus everywhere - and then I got here, and it wasn’t like that and there were mountains with trees, and stuff like that.

I thought it was really cool that I had to do maintenance on a UPS up in the mountains where there was no light anywhere at night, so you can see the stars for miles and the milky way galaxy and it’s just a pretty amazing experience to go to that facility.”

What do you think you’d be doing if you weren’t in critical power right now?

“I’d definitely be working - it could be anything. In the Navy, you’re expected to be a jack of all trades with many different skills conducting many different jobs because when you’re out at sea, there’s no one coming to rescue you, so you have to use these skills in order to help the ship complete its mission.

Besides, being an Electronics Mechanic, I also have experience repairing berthing HVACs, electronics cooling systems, hydraulic systems, and fire suppression sprinkler systems, to name a few.

Originally, I was going to get out of the Navy and be a welder, and I went through this program right as I was getting out to learn how to weld - to be a pipe welder- and then I went through 4 months of school, [and] got all these certifications."

What is something you are passionate about outside of work?

“I have many hobbies like gardening, raising chickens, raising Longhorn Cattle, restoring old vehicles. I’m currently building a cabin with my wife on our ranch doing the majority of the work ourselves. We weren’t really expecting to get cows but to keep our agriculture exemption on our land, we were required to have a certain number of livestock on the land.

We looked into getting 2 miniature longhorn cattle because they seemed like the easiest. Next thing you know, we fell in love with them, and they seem to multiply really fast so we have a nice little herd now. I’ve always had different types of animals growing up - dogs, rabbits, hamsters...”

What is the best advice you have ever received?

“Always prepare and learn new skills.

When I was in the Navy, the advice I always got from one of my favorite chiefs was to always prepare in case you get kicked out of the Navy tomorrow. So, what he meant by that was, you never know what life could bring you so you always want to be ready to present yourself or be marketable to a lot of different fields in case something happens.

So like, tomorrow, I could get hurt on the job and I’d still have a degree in Project Management where I’d be okay to just get an office job instead of being out in the field. I never intended to stay 20 years in the Navy so every time I came up on re-enlistment, I always prepared myself as if I was going to get out and go into the “real world."

I was constantly learning new jobs, getting new certificates. I have a certificate for journeyman license for being an electronics tester and a journeyman license [to be an] electrical mechanical technician. Anything that interests me, I’ll take a class in it and get certified in it and try to be a jack of all trades.”